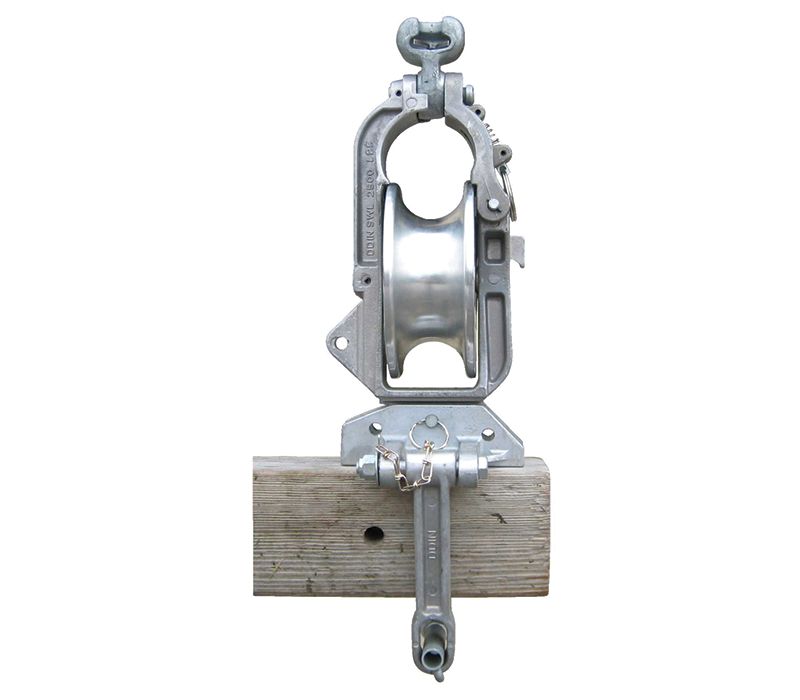

Transmission Blocks – 73 Series

Transmission-class line construction is very specialized. Structures are taller, spans are longer, conductors are larger/heavier/stiffer, and pulls are longer and can extend over steep and very uneven terrain. In addition, aluminum conductors vary in construction requirements, calling for special handling techniques, tools, and equipment.

Transmission construction also involves different line and structure designs, as well as

different conductor configurations. Some lines are strung using conventional, ground-based

equipment and tools, while others require stringing using helicopters.

The configuration and quality of the blocks in which sheaves are mounted are as important

as the sheaves.

About 73 Series Transmission Blocks

The 73 Series single-conductor stringing blocks are an ideal choice for reconductoring

mid-size-diameter conductor, especially when old conductor is used to pull in new conductor.

In addition to being available with 10″, 12″, 14″, and 16″ (OD) sheaves, they have an extra-large

throat, and do not have a conductor guard. This design permits easy passage of connections

between conductors and pulling lines, compression joints, swivels, and/or splices in the pulling line.

73 Series blocks are light-weight, yet exceptionally rugged, reliable, and durable. Their low-friction

bearings render high block efficiency, which helps to maximize stringing distances while minimizing

pulling tensions and reducing loads on stringing equipment. Combined with the associated family

of hardware and accessories, the 73 Series affords utilities and their contractors exceptional versatility

in how and where it may be deployed and in the range of installation problems it can help solve.

The 73 Series blocks’ light weight and durability derive from the materials and methods used to

make them. The material used for the frame is “virgin” A356-T6 Aluminum, which is an aluminum alloy

with very tightly controlled proportions of other materials to assure optimum performance during

manufacture and in the field. Virgin material is material that has not been mixed with scrap material,

not even with scrap of what may have once been the same alloy. That Sherman + Reilly uses “virgin”

material assures that the material is exactly and only the pure and correct alloy, and that it has not been

contaminated by impurities (notably iron) that often accompany non-virgin material.

73 Series frames are cast (molded) as molten metal. The properties and purity of the A356-T6 Aluminum

used by Sherman + Reilly assure that the molten metal flows smoothly and evenly throughout the mold,

assuring proper and uniform density throughout the finished frame. Proper density and uniformity

combined with the purity and metallic properties of the alloy assure that the frame is strong but

light-weight, and assure that there are no internal voids or brittleness that could cause sudden

complete failure of the block in the field.

The sheaves of the 73 Series are also made of the same virgin A356-T6 Aluminum as the frame.

They are also similarly cast, but they have the additional manufacturing step of having the grooves

and bearing surfaces machined for smoothness and precision fit. Combined with low-friction,

lubricated-for-life bearings, the sheave materials and how they are made assure high-efficiency

and smooth-stringing performance.

Specifications:

- Extra-wide throat to accommodate joints, swivels & connectors.

- 10 in, 12 in., 14 in. & 16” Sheaves.

- Available with polished-groove sheaves or lined with neoprene or urethane.

- High-strength Aluminum-alloy frames and sheaves.

- High-efficiency bearings, with provision for pressure-lubrication.

- Forever Warranty™