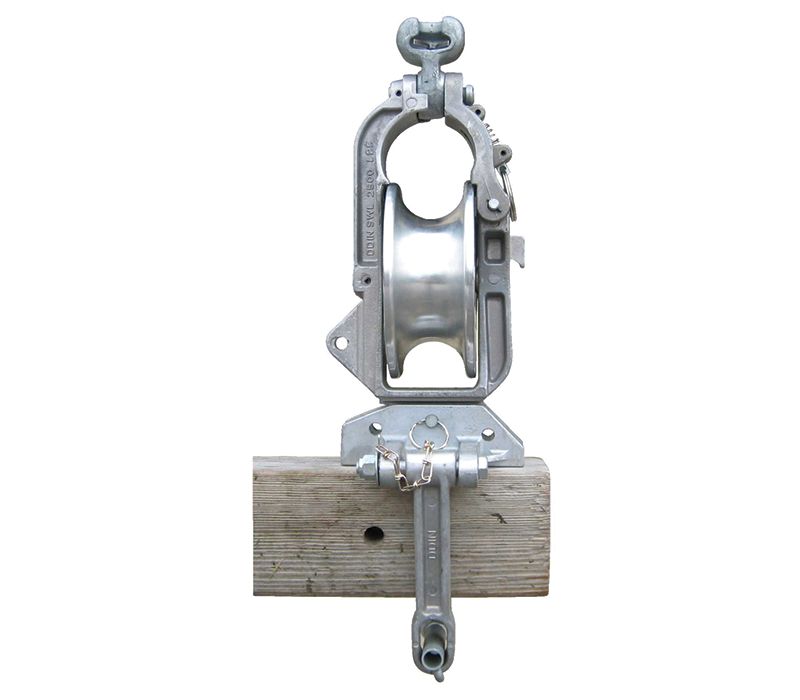

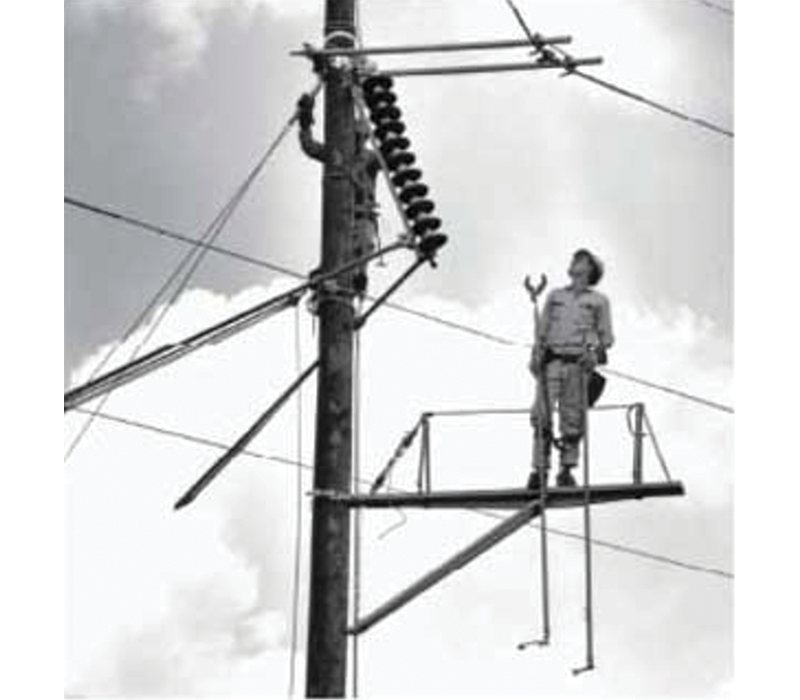

Transmission Insulator Cradle

Tested per OSHA & ASTM F711

This Chance Insulator Cradle is used to make insulator changes by supporting the string while damaged insulators are replaced, or to pivot the string so that it may be removed and lowered to the ground. On deadends or running corners these cradles are used in conjunction with strain carriers; and in straight suspensions they are used with various types of link sticks or adjustable strain pole assemblies.

The Transmission cradle is designed to be used on 69 kV to 115 kV deadend or suspension strings supported by a pair of wire tongs or link sticks.

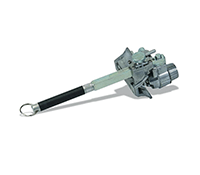

Insulator Cradles are made with three 1-1/2″ dia. Epoxiglas® poles. Light in weight, they are easy to handle and adaptable to many applications.

Lugs located at the forward end of the cradle are used to support the insulator string with a pair of wire tongs or link sticks. The back end of the cradle is supported by ropes tied at the structure. Hinged in this manner the insulators may be lowered or raised to the best position for changing damaged insulators.

In some cases, the cradle is supported in eyes located on the forward yoke of Two-Pole Strain Carriers. This is done when raising or lowering of the insulator string is unnecessary.

| Catalog No. | Overall Length | Recommended Capacity | Approx. Weight |

| H18406 | 6-ft. (180cm) | 10 10″ (250mm) Insulators | 19 3/4 lb./ 8.887 kg. |

| H18408 | 8-ft. (240cm) | 14 10″ (250mm) Insulators | 24 lb./11.262 kg. |

| H184010 | 10-ft. (300cm) | 18 10″ (250mm) Insulators | 27 lb./13.837 kg. |