Lifty Board

LIFTY BOARD device is PATENT PENDING tool that aids in the EFFICIENCY AND SAFETY with regard to maintenance work on open wire secondary and triplex (bundling). LIFTY BOARDTM device is especially useful when REPLACING UTILITY POLES.

Specifications:

LIFTY BOARDTM device OPTIONS

• Can be available in a 4 slot option

• Can be available in 10” spacing in between slots for larger conductor spacing

How it works

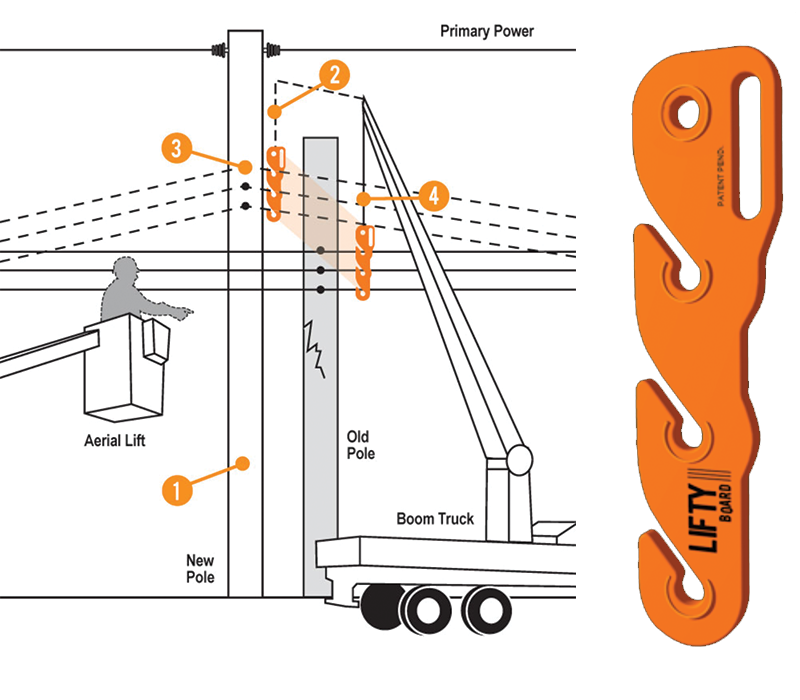

Step 1:

New utility pole is planted in the ground next to or in front of old pole. Primary power has already been connected to the new pole. The open wire secondary is attached to the clevises on the old pole. LIFTY BOARDTM device is raised from the winch line which is attached to the boom truck. Alternatively, you could attach LIFTY to the jib off of the bucket.

Step 2:

LIFTY BOARDTM device slots the 3 conductors into its 3 corresponding slots. The boom truck raises the conductors to maintain tension. The lineman can now disconnect the open wire secondary while LIFTY BOARDTM device holds the conductors in place. The old pole can be cut and removed from the area. This frees up space for the lineman to manoeuvre around the new pole. LIFTY BOARDTM device holds all 3 conductors at the same time.

Step 3:

LIFTY BOARDTM device is raised up to the new position on the new utility pole. The lineman connects the open wire secondary to the clevises on the new pole. Without LIFTY BOARDTM device, the lineman would have to disconnect and carry each conductor individually.

Step 4:

Unhook LIFTY BOARDTM device from the conductors and the job is complete. LIFTY BOARDTM not only reduces the amount of time it takes to perform this particular task, but it is much safer. LIFTY BOARDTM device minimizes direct contact with live wires carrying secondary distribution (240 volts). It also reduces heavy strain on your lineman.