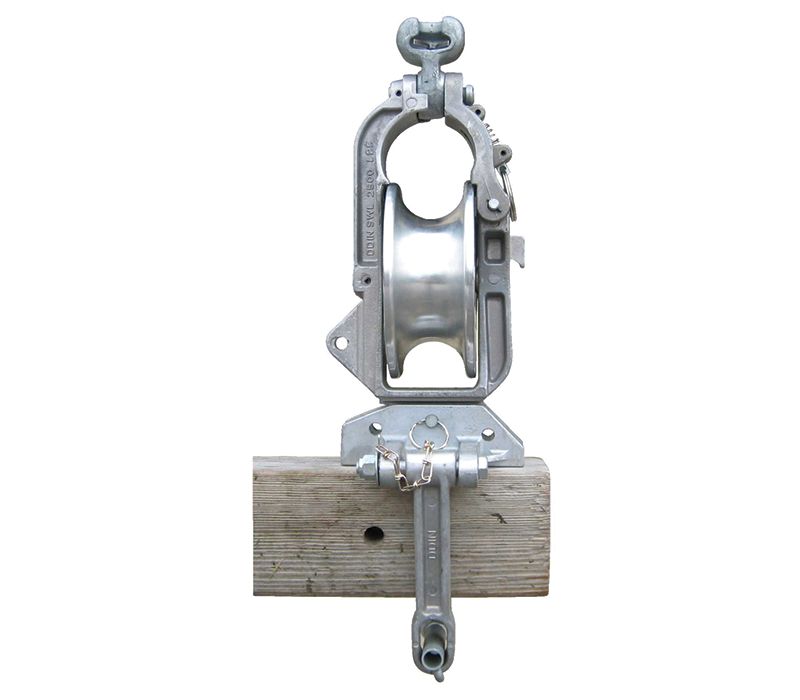

Transmission Blocks – 72 Series

- Configuration may be converted in the field.

- Configurations for 1, 2, 3, 3-offset, and 4 conductors.

- 20 in. – 42 in. sheaves

- Sheaves available as polished-groove or lined with neoprene or urethane.

- Available with choice of Y-clevis or head-bar hanger hardware.

- Forever Warranty™

About Transmission Construction

Transmission-class line construction is very specialized. Compared to distribution construction,

structures are taller, spans are longer, conductors are larger/heavier/stiffer, and pulls are longer

and can extend over steep and very uneven terrain. In addition, aluminum conductors vary in

construction requirements, calling for special handling techniques, tools, and equipment.

Transmission construction also involves different line and structure designs, as well as different

conductor configurations (including simultaneous stringing of multiple conductors (‘bundles”)

using a single pulling line). These configurations can range from single to bundles of two, three,

four, and six conductors per phase. Some lines are strung using conventional, ground-based

equipment and tools, while others require stringing using helicopters.

For all these reasons, the configuration and quality of the blocks in which sheaves are mounted

are as important as the sheaves.

About 72 Series Transmission Blocks

The Sherman + Reilly 72 Multiversal Series is a series of blocks that may be used in multiple

stringing configurations and afford the versatility of being reconfigurable in the field. That is,

these blocks may be converted in the field to accommodate one, two, three, three-offset, or four

conductors. With few exceptions, 72 Series blocks may be configured with 20″, 22″, 28″, 35”,

and 42″ (OD) sheaves.

The key to the versatility of the 72 Series is that all blocks are assemble from three basic components:

• Open-side, single-conductor block-frames

• Center-drum sections

• Sheaves

These three components are mixed and matched to configure blocks to meet the specific needs of

each project, then can be rearranged (in the field) to meet the needs of the next project.

The open-side single-conductor block-frame is a unique design that can support full loading from

one side of a single-conductor frame. The “open” side of the frame can then be mated with other

frame, drum, and sheave components to build out a complete block. This capability enables

combining single-conductor frame components with center sections and sheaves in mix-and-match

combinations to configure blocks to match a range of stringing needs.

When a 72 Series frame is assembled with only a throat guard and a single sheave, a single-conductor

block is created, and stringing single conductors with such a block is identical to stringing with a

conventional single-conductor block. The throat guard locks positively in position with the single-side

frame forming a completely enclosed area for the conductor. Although the guard locks positively in place,

it is easily unlocked for removal of the conductor after the sagging operation is complete and clipping

in is to be done.

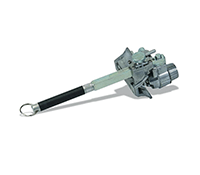

When 72 Series blocks need to be configured as bundle blocks, each block is assembled from two single-

conductor frames, sheaves, and center-drum sections, all mounted on a solid shaft. Blocks may be

configured that accommodate a separate steel pulling line, that have groove contours that accommodate

reconductoring, that maintain balance when pulling three conductors simultaneously with a separate

pulling line, and that have conductor groove contours that accommodate reconductoring.

For example, a 72 Series block may be configured as any of:

• A single-conductor block with throat-guard attachment.

• A two-conductor bundle block with a drum section to accommodate a pulling line.

• A three-conductor bundle block by assembling two single-conductor sections with a drum section

with conductor groove in the center.

• A four-conductor conductor bundle with a double-center drum with two conductor grooves.

Regardless of configuration, all sheaves and center-drum sections turn on low-friction (high-efficiency)

ball bearings, and each rotates independently from the others.

In addition to the versatility afforded by reconfigurability, 72 Series blocks are available in any of the

three designs that Sherman & Reilly offers: symmetrical, slim-line, oroffset. More about the

significance of these designs is below.

72 Series frames, sheaves, and center-drums are all cast from virgin A356-A6 Aluminum, an alloy

that renders light weight, exceptional ruggedness, reliability, and durability. The properties and

purity of the A356-T6 Aluminum used by Sherman & Reilly assure that the molten metal flows

smoothly and evenly throughout the casting mold, assuring proper and uniform density throughout

the finished part. Proper density and uniformity combined with the purity and metallic properties

of the alloy assure that parts are strong but light-weight, and assure that there are no internal voids

or brittleness that could cause sudden complete failure in the field. Combined with low-friction,

lubricated-for-life bearings in the sheaves, the materials used for the parts and how the parts are

made assure high-efficiency and smooth-stringing performance. The high block efficiency helps

to maximize stringing distances while minimizing pulling tensions and reducing loads on

stringing equipment.