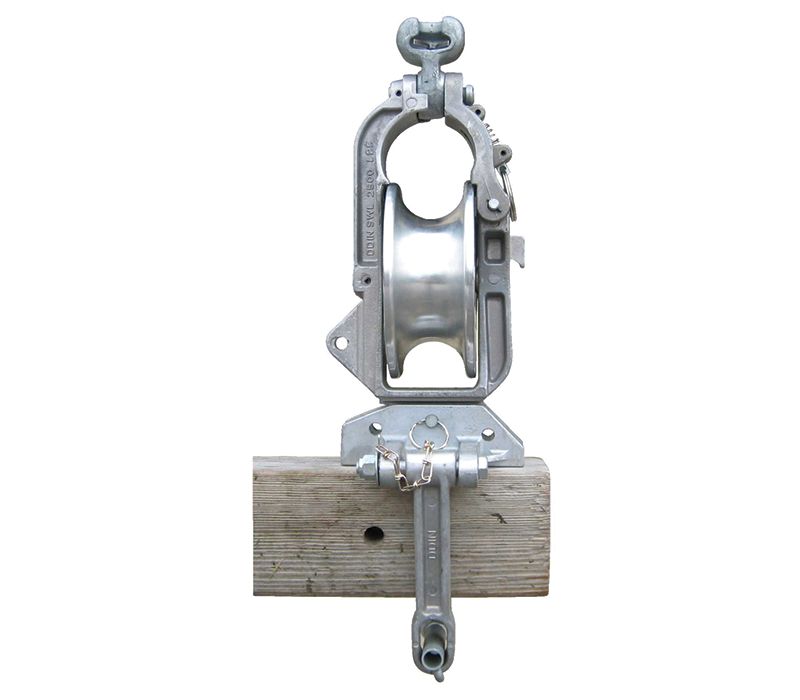

Sheaves for Transmission Blocks

The sheaves described below are those that fit Sherman + Reilly 70 Series, 72 Series, 73 Series, 74 Series, and 78 Series blocks. All are made from the best materials for their purpose and are manufactured to render high performance, durability, and being easy on conductor. All turn on low-friction, sealed, lubricated-for-life ball bearings, which render 98% efficiency and assure long-term reliability and smooth, minimum-load stringing.

Three types of sheaves are available for Sherman + Reilly transmission blocks:

Polished-Groove Aluminum

Sherman + Reilly polished-groove sheaves are made entirely of (virgin) A356-T6 Aluminum, which

is the same material used for 72 Series, 73 Series, 74 Series, and 78 Series block frames, and which

renders high-strength with light weight. The use of virgin materials and the manufacturing process

together help assure that the sheaves are uniformly dense, with controlled impurities, and without

voids, which help assure long life and help assure against sudden failure.

Polished-groove sheaves are very durable and are easy on common conductors. Consequently, blocks

with polished-groove sheaves make a good choice for stringing common conductors under typical,

non-energized conditions.

Urethane Lining on Aluminum

Sherman + Reilly urethane-lined aluminum sheaves are made identically to polished-groove sheaves

(above) except that a premium-grade polyurethane lining is cast-in-place on the sheaves’ conductor-

contact surface. The properties of the urethane and casting it in place on the bare sheave together

assure a high-precision profile of the lined sheave. The urethane’s formulation assures resiliency to

cushion conductors, as well as assures hardness, high load-bearing capacity, impact resistance,

abrasion resistance, resistance to compression-set, and resistance to oil, ozone, and other

environmentals – all of which contribute to long useful life, even under harsh field conditions.

A-scale durometer hardness of the lining is 90-92.

Blocks with urethane-lined sheaves are especially appropriate for stringing conductor, static wire,

and fiber optic cables.

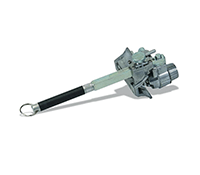

Neoprene Lining on Aluminum

Sherman + Reilly neoprene-lined aluminum sheaves are made identically to polished-groove

aluminum sheaves except that a semi-conductive neoprene lining is applied to the sheaves’

conductor-contact surface. The neoprene is vulcanized and post-cured to assure consistency and

uniformity. In addition to its conductive properties and acting as a cushion for the conductor,

neoprene lining has high abrasion resistance and durability. A-scale durometer hardness of the

lining is 70-72.

Blocks with neoprene-lined sheaves help to conduct potentially harmful voltages/currents to

ground during stringing operations. Blocks with neoprene-lined sheaves are, consequently,

especially appropriate for stringing in energized environments or in any environment where

there is potential for induced or contact voltages/currents.

How to Select Transmission Sheaves

Determining which sheave to use is a simple matter of determining the appropriate size and

appropriate lining (if any).

The appropriate size is a simple function of the type/size of conductor being strung, the distance

of the ruling span, and the difficulty of the terrain. A calculator tool that can aid you in determining

the appropriate sheave size is available in the Publications section of this page, or you may refer to

IEEE Standard 524™ (2003), which is available from IEEE.

Sheave size determines your choices of block frame, and not all sheave sizes are available in all

block frames. Larger sheaves require larger and more robust frames, and other factors related to

the conductor, span distance, terrain, and bundle configuration affect the block choice. So, once

you have determined the appropriate sheave size, you may then select the appropriate block

frame/design that best suits the specifics of your stringing project. Dimensional diagrams/tables

and how sheave sizes match up with each block Series are described in the Sheave Dimensions

& Specifications Table in the Publications section of this page.

The appropriate lining, if any, is a function of the conductor (or cable) type and the conditions that will

exist during stringing operations. The lining is then chosen to match the conductor type and the stringing

conditions, often with direction from the conductor manufacturer.

Specifications:

- High strength, low weight.

- High-efficiency, low-friction.

- Polished groove or urethane- or neoprene-lined.

- High maximum working loads.

- Forever Warranty™