Underground Puller – U7500

PRODUCT #U7500

The Sherman + Reilly Revolution Series U7500 is a bullwheel puller for the installation of underground distribution conductor. The single platform, modular design provides 7,500 lbs. pulling capacity offering plenty of power to handle most installations. The hydraulically driven twin capstan bullwheels ensure smooth, well-controlled pulls.

Powered by a 35 hp 4-cylinder diesel engine, the transmission has two forward speeds and a reverse demand payout. The U7500 has plenty of power as well as flexibility to deal with varying needs during an underground pull. A joystick-controlled, hydraulically positioned extendable boom with 170° of swing arc is available for reaching into and pulling from pad-mounted transformers and other tight openings.

With state of the art design to ensure operator safety, the U7500 features a Safe Zone Cab™. This enclosure is designed to keep an operator off the ground while the equipment is in use. Built with a fully adjustable, ergonomic seat and a digital touch display for all machine operations, diagnostics, and pull status. The Safe Zone™ Cab is designed to reduce operator fatigue thereby reducing errors and injuries in the field.

Equipped with a digital electronic load recorder for documenting pulling tensions and an electronic footage counter providing accurate, and continuous measurement of conductor/cable deployed. Optional on-board air compressor.

| Pulling Capacity, max.: | 7,500 lb. |

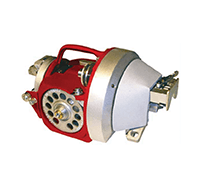

| Bullwheels: | Twin capstan, 6 in. dia., 5-groove followed by 6-groove |

| Gearbox & Line Speed: | 1st gear: 0-60 fpm @ 7,500 lb.; 2nd gear: 0-120 fpm @ 3,500 lb.; reverse: 0-300 fpm demand payout |

| Drive System: | Hydraulic |

| Hydraulic Fluid: | ISO Grade 32 |

| Hydraulic Reservoir: | 22 gal. |

| Engine: | 35 hp, Diesel, water-cooled, electric start |

| Fuel Capacity: | 18 gal. (25 gal. when equippped with air compressor) |

| Pulling Rope: | 3/8 in., 6 x 25 XIP IWRC steel wire rope, 2000 ft. |

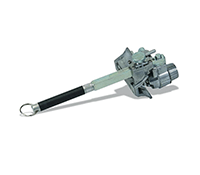

| PTMA/Boom: | Hydraulic, joystick-controlled, 3-axis, 170º swing arc, 80 in. stored length + 30 in. extension |

| Boom Camera: | CCD, swivel-mounted at end of boom, cab display |

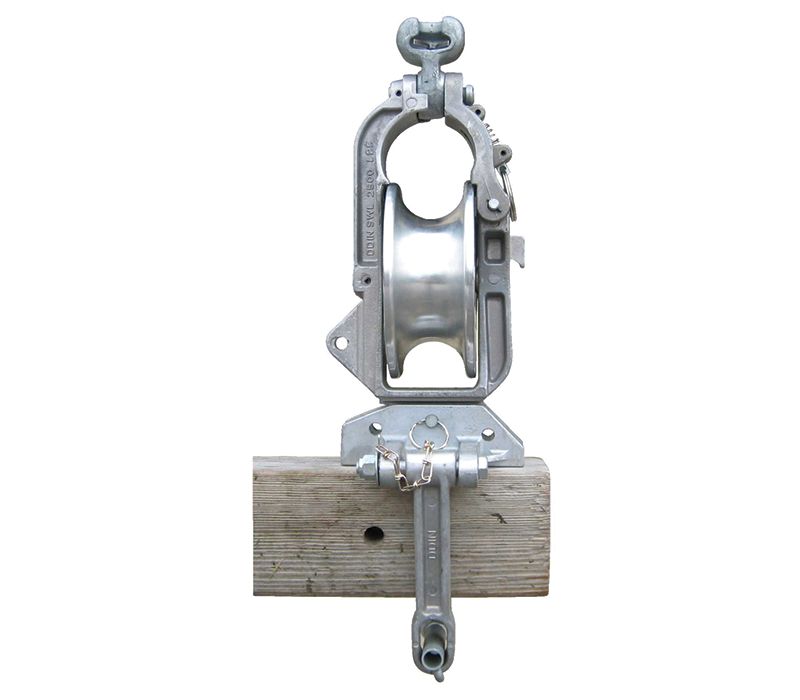

| Levelwind: | Dual automatic fairlead sheaves |

| Operator’s Safety Enclosure: | Safe-Zone Cab, full enclosure with A/C and heat |

| Controls: | All at control panel within cab: engine & pulling; digital instrumentation; emer. stop; tensiometer; video diplay |

| Wireless Controls: | Winch speed & direction and emer. stop; 900 Mhz ISM band |

| Footage Counter: | Electronic, actual footage, pay-in & pay-out |

| Hydraulic Tool Circuit: | 7 gpm @ 2,000 psi, auxiliary for hand tools, pumps, etc. |

| Pulling Connectors: | Rotation-resistant: 1 ea. rated 3,000 lb. & 1 ea. rated 8,000 lb. included |

| Frame Construction: | Steel tubing, continuous-weld |

| Length, overall, nom.: | 20 ft. |

| Width, overall, nom.: | 7 ft., 3 in. |

| Height, overall, nom.: | 7 ft., boom stored |

| Weight, nom.: | 6,500 lb., with rope, w/o air compressor (7,000 lb. w/ compressor) |

| GVWR: | 9,800 lb. |

| Suspension: | Leaf spring |

| Axle Configuration: | Single |

| Wheel Configuration & Tires: | Single, LT235/75R17.5 |

| Brakes, trailer: | Electric, with safety break-away switch |

| Towing Attachment: | 3 in. adjustable pintle eye |

| Safety Chains: | 2 ea., with hooks |

| Front/Nose Jack: | Hydraulic, part of auto-leveling system, with shoe |

| Stabilizing Jacks: | Hydraulic, part of auto-leveling system, with shoes |

| Electrical System: | 12 VDC, 45 A alternator |

| Lights, navigation: | US DOT LED, 12 VDC (stop, tail, turn, clearance) |

| Lights, illumination: | Cab-top floods (2 ea.), cab-interior dome |

| Battery: | 12 VDC, 525 CCA |

| Grounding: | 3/4 in. dia. copper-clad steel ground loops, 4 ea. |

| Tool Box: | Steel, lockable, complete set of tools, and E-35D & E-49D connectors |

| Fire Extinguisher: | ABC |

| Cover, protective: | Vinyl, for rope drum |

| Paint: | S+R white |