TSM, T, SM & S Series Blanket Testing Equipment

Automatic Testing rubber blankets

Up to 40,000V AC, 100,000V DC or both

Allows Testing to ASTM D1048 and F479 Standards

Up to 40,000V AC, 100,000V DC or both

Allows Testing to ASTM D1048 and F479 Standards

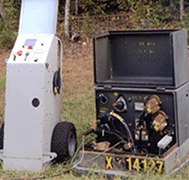

The TSM Series is The VON Corporation’s fully automated blanket test solution. Units allow testing of all standard rubber blankets, even class IV. Tests are timed and an audible alarm sounds failures or test complete, with bright flashing colored lights signaling which position failed or test complete. Four and Eight position models are available.

CAPACITY:The TSM four drawer machine will automatically and simultaneously test four or eight insulated blankets at voltages to 50,000 volts A.C. or 70kV DC, depending on purchased options. The SP series is a four drawer machine that will provide the same tests when slaved to a master rubber goods testing machine, dependent on that master’s high voltage capabilities. These machines are capable of testing blankets as large as 46″ x 46″. With the proper electrodes all standard insulating rubber protective blankets may be tested in accordance with the latest ASTM D1048 and F479 standards.

VOLTAGE: The input voltage is 120/240 volt A.C. single phase. The TSM series has 0-50,000 volts A.C. test voltage provided by a 12kva continuous duty transformer. The TSM-DC series has 0-80,000 volt D.C. supply. The TSM-ACDC series contains both supplies and a transfer switch for changing between the high voltage supplies. The test voltage is measured by means of a resistive divider connected directly across the high voltage circuit. An LCD diplays the output voltage both digitally and with a bar graph. The test voltage is raised and lowered with a special solid state device at a rate of approximately 1 kilovolt A.C. or 3 kilovolt D.C. a second.

CURRENT: The current of each being being tested is continuously monitored by the microprocessor control system. The active current leakage as well as the peak current is displayed on an LCD display both digitally and with a bar graph.

VENTILATION: One 1600 cfm exhaust fan is provided in the top rear of the blanket testing cabinet to remove ozone.

ENCLOSURE: Eyebolts are provided in the top for lifting by a crane. An interlocked front access door is provided in the power supply and control area.

CONTROLS: :A menu based system provides all controls from the front control panel. All standard tests come predefined for the user. These predefined tests set all the machines settings and automatically run the test on the specified class of blanket. There are also 4 user defined test modes available, as well as a mode for manual control of the entire system.

INDICATORS: All LED light indicators operate in a fail safe mode by being lighted at all times. The lights flash when indicating. A red “HIGH VOLTAGE FAILURE” light is provided on each drawer. A red ” FAIL” light and a green “TEST COMPLETE” light are provided on the control panel. The LCD current display shows the current leakage current, as well as saving the peak current. After a failure the LCD display also indicates which blankets failed.

OPERATION: A blanket is loaded into each drawer to be tested. The top electrode in each drawer is lowered into position when its toggle switch is turned to the “TEST” position. The operator selects the voltage class to be tested from the menu, and pushes the “START” button. From one to four blankets as selected by the operator will be simultaneously tested. Eight position machines allow alternate loading of two two sets of four drawers.

The automatic high voltage cycle includes raising and lowering the voltage to the setpoint, automatic timing of the test, and automatic visual and audible indication of blanket pass or fail. A blanket which fails will stop the test, cause a steady audible signal, indicate which drawer has failed, and discharge any remaining voltage.

The surface of the blanket testing drawer is made of ozone resistant plastic with a non-tracking coating. This permits both the top and bottom electrodes to be the similar size so that the maximum area of the blanket can be tested. The aluminum electrodes are held in position by locating pins. The drawer is the grounded electrode. The high voltage electrode is mounted on a movable insulating frame. One size of electrode is provided with each drawer. Unless specified electrodes are provided for testing 36″ x 36″ blankets rated Class I to Class III. For other sizes and ratings please specify the blanket size, shape, and voltage class. Additional electrodes are available for each drawer.