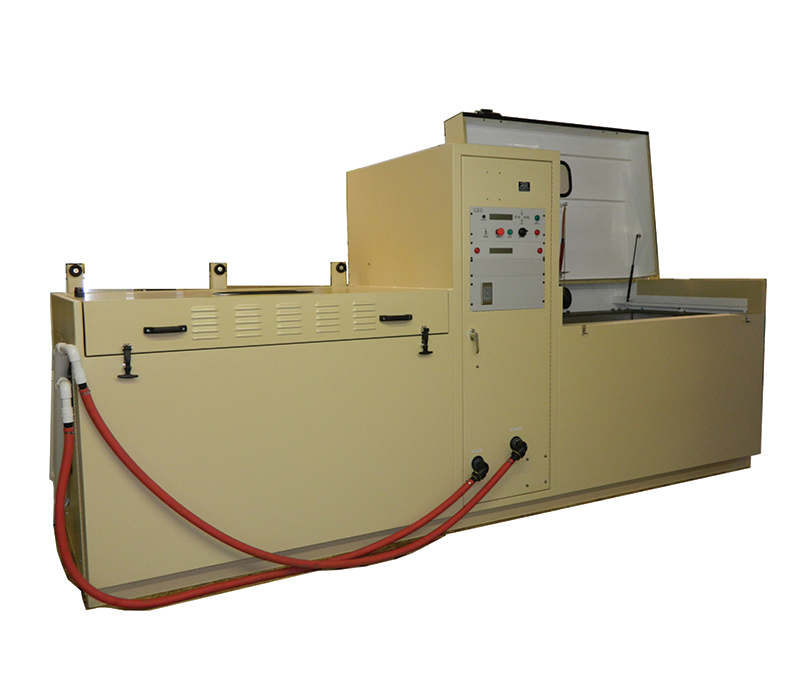

TWM, WM Series Basket Liner Testing Equipment

Automatic Testing of Aerial Device Basket Liners

Handles TECO & Hi-Ranger double bucket liners.

Allows Testing to ANSI A92.2, CSA and IEC Standards

The TWM Series is The VON Corporation’s fully automated bucket liner/basket test solution. Units allow testing of all standard and double bucket liners. Test voltage and arc detection are all controlled electronically. Tests are timed and an audible alarm sounds failures or test complete, with bright flashing colored lights signaling which position failed or test complete.

CAPACITY: The TWM or WM machine will automatically test bucket liners/baskets at voltages to 40,000 volts A.C. or 100kV DC. Two position machines include an automatic transfer switch to allow alternate loading of the two test bays. Tests can be made in accordance with the latest ANSI A92.2 and comparable international standards.

VOLTAGE: The input voltage is 120/240 volt 60 hertz A.C. single phase. AC units have a 0-50,000 volts A.C. test voltage provided by an 18kva continuous duty transformer. DC units have a 0-100,000 volt D.C. supply. The test voltage is measured by means of a resistive divider connected directly across the high voltage circuit. An LCD diplays the output voltage both digitally and with a bar graph. The test voltage is raised and lowered with a special solid state device at a rate of approximately 1 kilovolt A.C. or 3 kilovolt D.C. a second.

CURRENT: The current of each bucket is continuously monitored by the microprocessor control system. The active current leakage as well as the peak current is displayed on an LCD display both digitally and with a bar graph.

VENTILATION: Exhaust fans are provided in the rear of the each testing cabinet to remove ozone.

ENCLOSURE: Eyebolts are provided in the top for lifting by a crane. An interlocked front access door is provided in the power supply and control area.

CONTROLS: A menu based system provides all controls from the front control panel. All standard tests come predefined for the user. These predefined tests set all the machines settings and automatically run the test on the specified class of glove or sleeve. There are also 4 user defined test modes available, as well as a mode for manual control of the entire system. INDICATORS: All LED light indicators operate in a fail safe mode by being lighted at all times. The lights flash when indicating. A red “HIGH VOLTAGE FAILURE” light is provided for each position. A red ” FAIL” light and a green “TEST COMPLETE” light are provided on the control panel. The LCD current display shows the current leakage current, as well as saving the peak current. After a failure, the LCD display also indicates which gloves failed.

OPERATION: The operating cycle begins after the operator selects the test type from the menu, which automatically adjusts the test time, voltage, current limit, and exhaust fan speed with a single setting. If the type is not changed from the last test, then no menu selection is required. Next the item to be tested are mounted in the machine. Then the operator simply pushes the “START” button.

The high voltage cycle consists of raising the test voltage to the set value, automatic timing of the test duration, automatic flashing lights for failed buckets, audible indication of failed goods, and the lowering of the test voltage. At the end of all tests without a high voltage failure, a green “TEST COMPLETE” light flashes, and pulsating audible signal sounds.